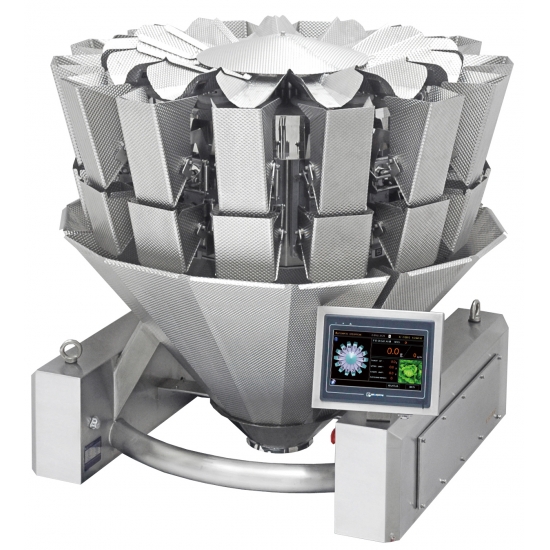

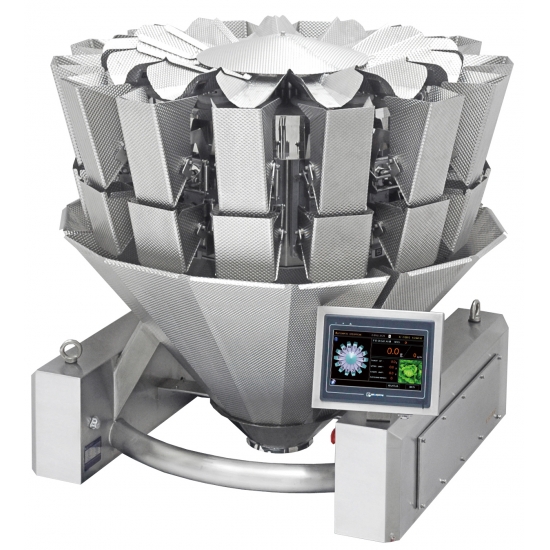

What is the adjustment principle of the multi-head combination weigher?

The multi-head combination weigher adjustment principle is simply composed of multiple independent weighing units with feeding and discharging structures. The computer uses the principle of permutation and combination to automatically optimize and combine the load of the weighing unit to obtain the closest target weight value. The weight combination is packaged.

Multi-head combination weigher, also known as combination weighing instrument, is used for rapid quantitative weighing and packaging of granular, strip, and irregular materials.

Its working principle is as follows: the adjustment of the multi-head combination weigher solves the problem of material falling by installing a buffer cylinder at the outlet of the discharge cone, and the partition installed in the buffer cylinder and the semicircular baffle set at the outlet of the discharge cone make The material channel has changed from the original one to two. After the weighed material is discharged from the weighing hopper into a flow channel of the buffer cylinder through the discharge cone, the semicircular baffle is overturned, and the weighing hopper weighs the next batch. The well-measured materials are discharged into another channel, thereby saving the circulation time of materials in the buffer cylinder, speeding up the weighing speed of the multi-head scale, and improving the weighing efficiency.

The structure of the multi-head combination weigher includes a circular feeding tray; a vibrating feeder; a feeding hopper; a weighing hopper; a discharge cone; a buffer cylinder; a partition; a semicircular baffle; a hinge rod; a bending rod; and a pushing device. The adjustment principle of the multi-head combination weigher means that when the multi-head combination weigher is working, the materials to be weighed (peanuts, melon seeds, etc.) are evenly distributed into the hopper through the vibration of the circular feeding tray, and the hopper sends the materials to the weighing hopper. In each weighing hopper, the materials in it are individually weighed. The CPU on the main board reads and records the weight of each weighing hopper, and then calculates, analyzes, combines, and filters to select the combination that is closest to the target weight. The weighing hopper opens its discharge plate for discharging. After the material enters a flow channel of the buffer cylinder through the discharge cone, the semicircular baffle is turned over, and the weighing hopper discharges the next batch of weighed materials into another channel. , Thus saving the circulation time of materials in the buffer cylinder, speeding up the weighing speed of the multi-head scale, and improving the weighing efficiency.

Therefore, this principle not only solves the problem that the material falling due to gravity and inertia affects the weighing accuracy, but also improves the weighing efficiency.

Its working principle is as follows: the adjustment of the multi-head combination weigher solves the problem of material falling by installing a buffer cylinder at the outlet of the discharge cone, and the partition installed in the buffer cylinder and the semicircular baffle set at the outlet of the discharge cone make The material channel has changed from the original one to two. After the weighed material is discharged from the weighing hopper into a flow channel of the buffer cylinder through the discharge cone, the semicircular baffle is overturned, and the weighing hopper weighs the next batch. The well-measured materials are discharged into another channel, thereby saving the circulation time of materials in the buffer cylinder, speeding up the weighing speed of the multi-head scale, and improving the weighing efficiency.

The structure of the multi-head combination weigher includes a circular feeding tray; a vibrating feeder; a feeding hopper; a weighing hopper; a discharge cone; a buffer cylinder; a partition; a semicircular baffle; a hinge rod; a bending rod; and a pushing device. The adjustment principle of the multi-head combination weigher means that when the multi-head combination weigher is working, the materials to be weighed (peanuts, melon seeds, etc.) are evenly distributed into the hopper through the vibration of the circular feeding tray, and the hopper sends the materials to the weighing hopper. In each weighing hopper, the materials in it are individually weighed. The CPU on the main board reads and records the weight of each weighing hopper, and then calculates, analyzes, combines, and filters to select the combination that is closest to the target weight. The weighing hopper opens its discharge plate for discharging. After the material enters a flow channel of the buffer cylinder through the discharge cone, the semicircular baffle is turned over, and the weighing hopper discharges the next batch of weighed materials into another channel. , Thus saving the circulation time of materials in the buffer cylinder, speeding up the weighing speed of the multi-head scale, and improving the weighing efficiency.

Therefore, this principle not only solves the problem that the material falling due to gravity and inertia affects the weighing accuracy, but also improves the weighing efficiency.

粤公网安备44011302001191号 | 粤ICP备16015233号

粤公网安备44011302001191号 | 粤ICP备16015233号