How Does a Multihead Weigher Work?

Also known as combination scales, multi-head weighers use a number of different weigh heads to generate precise measurements of products by calculating the weight in each weigh head. Each weigh head has its own precision load cell.

At a basic level, a multi-head weigher takes bulk product and weighs it into smaller increments according to the weights programmed into its software.

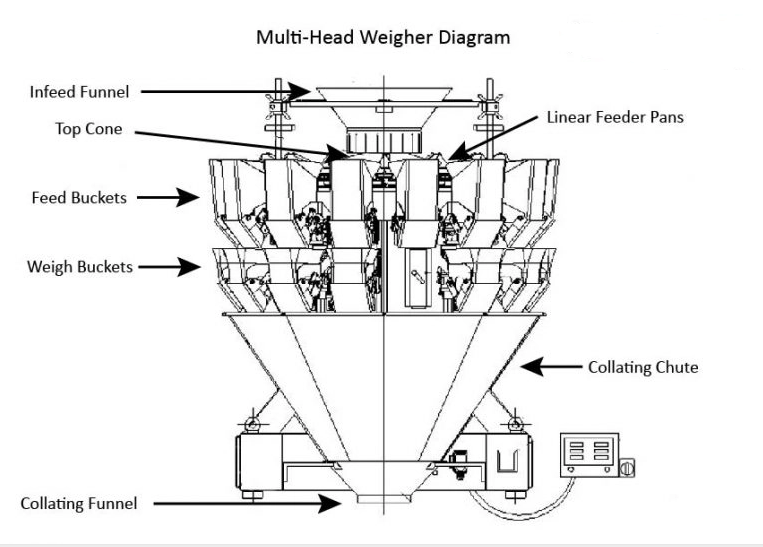

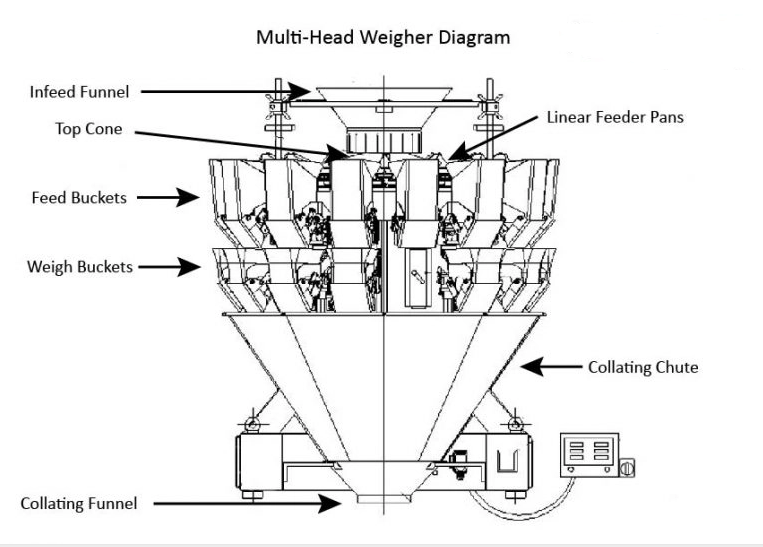

That bulk product is fed into the scale through the infeed funnel at the top, generally via an incline conveyor or a bucket elevator.

Diagram of Multi-Head Weigher Parts

The top cone and feed pans vibrate, and gently move that product out from the center toward the buckets mounted around the edge of the scale. The system has various options and software settings which are adjusted for the product and fill weight.

The top cone and feed pans vibrate, and gently move that product out from the center toward the buckets mounted around the edge of the scale. The system has various options and software settings which are adjusted for the product and fill weight.

For some applications, the scale will have dimpled steel contact surfaces, which provide less surface area for sticky products – such as gummies – to stick to. The sizes of the buckets also vary based on the product being weighed and the fill amount. While every application is different, bulkier product and/or larger containers generally leads to larger buckets (while the inverse is also true).

Each of the weigh buckets has its own load cell, which are constantly weighing the amount of product they contain, all while product continues to feed into them.

In order to reach the target weight, the software of the scale chooses the sum of a combination of buckets which add up to the correct amount.

The two main advantages of combination weighers are speed and accuracy.

Each weigh hopper is equipped with a highly accurate load cell. This load cell will calculate the weight of product in the weigh hopper. The processor in the multihead Weigher will then calculate the best combination of available weights required to achieve the desired target weight. This is why Multihead weighers are sometimes referred to as Combination weighers.

In addition, a multi-head weigher does not face the same issues with weighing clumps that might be present in a linear scale.

The other main advantage is speed. Because each of the heads on the scale are constantly replenishing and weighing the amount of product they contain, they can move much faster than an operator using a manual scale.

Gantan’s standard multi-head weighers range from 10 to 14 heads. The more weighing heads a scale has, the more options its computer has when trying to create combinations which hit the correct amount, which ultimately leads to higher possible speeds and better accuracy.

The commitment of Gantan is to design and provide Chinese made multihead weighing solutions with premium quality and standards. Please contact us immediately gantan@gtpack.com.

粤公网安备44011302001191号 | 粤ICP备16015233号

粤公网安备44011302001191号 | 粤ICP备16015233号